Stainless steel plates refer to steel plates that are resistant to corrosion by weak media such as atmosphere, steam and water, while acid-resistant steel plates refer to steel plates that are resistant to corrosion by chemically corrosive media such as acids, alkali and salts.

chemical composition:

304 stainless steel grade: 0Cr18Ni9 (0Cr19Ni9) 06Cr19Ni9 S30408

Chemical composition: C: ≤0.08, Si: ≤1.0 Mn: ≤2.0, Cr: 18.0~20.0, Ni: 8.0~10.5, S: ≤0.03, P: ≤0.035 N≤0.1.

with 304L

304L is more corrosion-resistant, and 304L contains less carbon.

304 is widely used, with good corrosion resistance, heat resistance, low temperature strength and mechanical properties; good hot workability such as stamping and bending, and no heat treatment hardening phenomenon (non-magnetic, service temperature -196°C~800°C).

304L has excellent resistance to grain boundary corrosion after welding or stress relief; it can also maintain good corrosion resistance without heat treatment, and the service temperature is -196°C-800°C.

Basic Situation:

According to the production method, it is divided into two types: hot rolling and cold rolling. According to the structural characteristics of the steel type, it is divided into 5 categories: austenite, austenite-ferrite, ferrite, martensite, and precipitation hardening. It is required to withstand the corrosion of various acids such as oxalic acid, sulfuric acid-iron sulfate, nitric acid, nitric acid-hydrofluoric acid, sulfuric acid-copper sulfate, phosphoric acid, formic acid, acetic acid and other acids. It is widely used in chemical industry, food, medicine, papermaking, petroleum, atomic energy, etc. Industry, as well as construction, kitchen utensils, tableware, vehicles, various parts of household appliances.

The stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion by acids, alkaline gases, solutions and other media. It is an alloy steel that is not easy to rust, but it is not absolutely rust-free.

Stainless steel plates are divided into two types: hot rolling and cold rolling according to the production method, including thin cold plates with a thickness of 0.02-4 mm and medium and thick plates with a thickness of 4.5-100 mm.

In order to ensure that the mechanical properties such as yield strength, tensile strength, elongation and hardness of various stainless steel plates meet the requirements, the steel plates must undergo heat treatment such as annealing, solution treatment, and aging treatment before delivery 05.10 88.57.29.38 Special symbols

The corrosion resistance of stainless steel mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, etc.) and internal organizational structure. The main role is chromium. Chromium has high chemical stability and can form a passivation film on the surface of steel to isolate the metal from the outside world, protect the steel plate from oxidation, and increase the corrosion resistance of the steel plate. After the passivation film is destroyed, the corrosion resistance decreases.

National standard nature:

Tensile strength (Mpa) 520

Yield strength (Mpa) 205-210

Elongation (%) 40%

Hardness HB187 HRB90 HV200

The density of 304 stainless steel is 7.93 g/cm3. Austenitic stainless steel generally uses this value. 304 chromium content (%) 17.00-19.00, nickel content (%) 8.00-10.00, 304 is equivalent to my country’s 0Cr19Ni9 (0Cr18Ni9) stainless steel.

General characteristics:

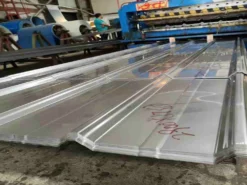

304 stainless steel plate has beautiful surface and diversified use possibilities

Good corrosion resistance, better corrosion resistance than ordinary steel

High strength makes it possible to use thin sheets

Resistant to high temperature oxidation and high strength, thus resistant to fire

Processing at room temperature, i.e. easy plastic processing

Simple and easy maintenance because no surface treatment is required

Clean, high finish

Good welding performance