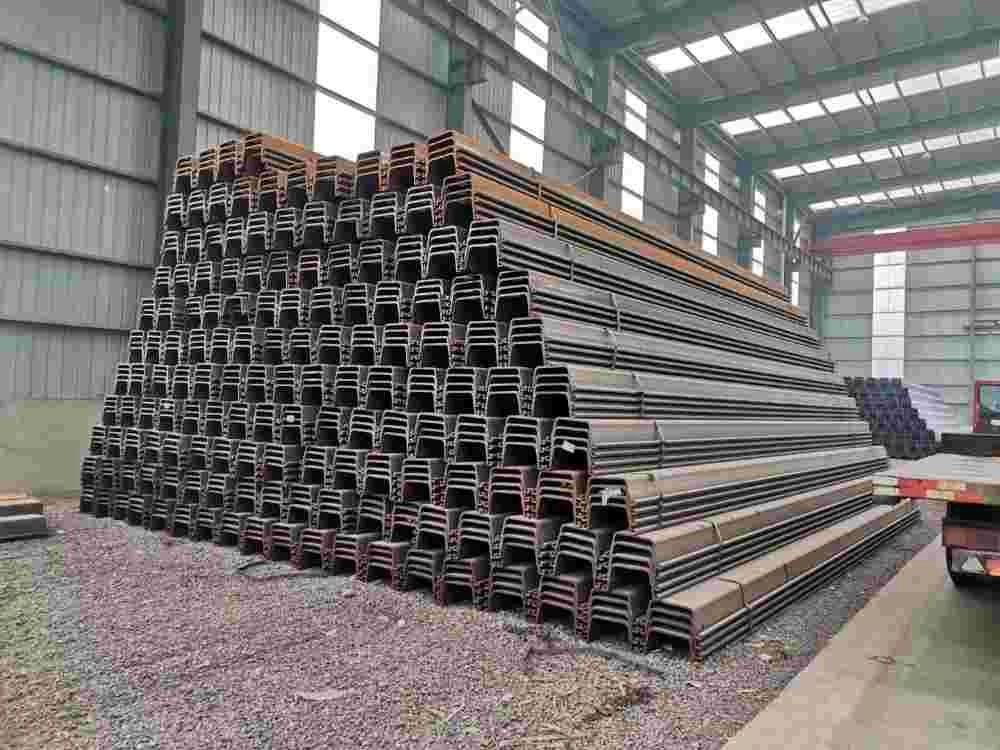

Steel sheet pile is a steel structure with linkage devices on the edges, and the linkage devices can be freely combined to form a continuous and tight retaining soil or water retaining wall.

-Classification:

Sheet pile products are divided into two types according to production technology: cold-formed thin-walled steel sheet piles and hot-rolled steel sheet piles.

(1) Cold-formed steel sheet piles include non-bite type cold-formed steel sheet piles (also called channel plates) and bite-type cold-formed steel sheet piles (divided into L-type, S-type, U-type, and Z-type) . Production process: Thin plates (commonly used thickness 8mm ~ 14mm) are continuously rolled and formed in a cold bending unit. Advantages: less investment in production lines, lower production costs, and flexible product length control. Disadvantages: The thickness of all parts of the pile body is the same, the cross-sectional size cannot be optimized, resulting in an increase in the amount of steel used, the shape of the locking part is difficult to control, the joints are not fastened tightly, and water cannot be sealed, and the pile body is prone to tearing during use.

(2) Hot-rolled steel sheet piles. Hot-rolled steel sheet piles in the world mainly include U-type, Z-type, AS-type, H-type and dozens of specifications. The production, processing and installation processes of Z-shaped and AS-shaped steel sheet piles are relatively complex and are mainly used in Europe and the United States; in China, U-shaped steel sheet piles are mainly used. Production process: It is formed by high-temperature rolling in a section steel rolling mill. Advantages: standardized size, superior performance, reasonable cross-section, high quality, and tight water-proof lock bite. Disadvantages: greater technical difficulty, higher production costs, and inflexible specification.

-Shape Catelogue

U-shaped steel sheet pile: WRU7 WRU8 WRU9 WRU10-450 WRU11-450

Advantages:

1) U-shaped steel sheet piles are available in various specifications and models.

2) Designed and produced according to European standards, the structure is symmetrical, which is conducive to repeated use and is equivalent to hot rolling in terms of repeated use.

3) The length can be specially customized according to customer requirements, which brings great convenience to construction and also reduces costs.

4) Due to the convenience of production, when used with combined piles, they can be pre-ordered before leaving the factory.

5) The production design and production cycle are short, and the performance of steel sheet piles can be determined according to customer requirements.

Z-shaped steel sheet pile: WRZ16-635 WRZ18-635 WRZ28-635

The locks are symmetrically distributed on both sides of the neutral axis, and the web is continuous, which greatly improves the section modulus and bending stiffness and ensures that the mechanical properties of the section can be fully exerted. Because of its unique cross-sectional shape and reliable Larssen lock.

Advantages of Z-shaped steel sheet piles:

1. Flexible design, with relatively high section modulus and mass ratio;

2. Higher moment of inertia, thereby increasing the stiffness of the sheet pile wall and reducing displacement and deformation;

3. Large width, effectively saving time on hoisting and piling;

4. The increased cross-section width reduces the number of shrinkage of the sheet pile wall and directly improves its water-stopping performance;

5. The parts with severe corrosion are thickened to make the corrosion resistance even better.