Introduction

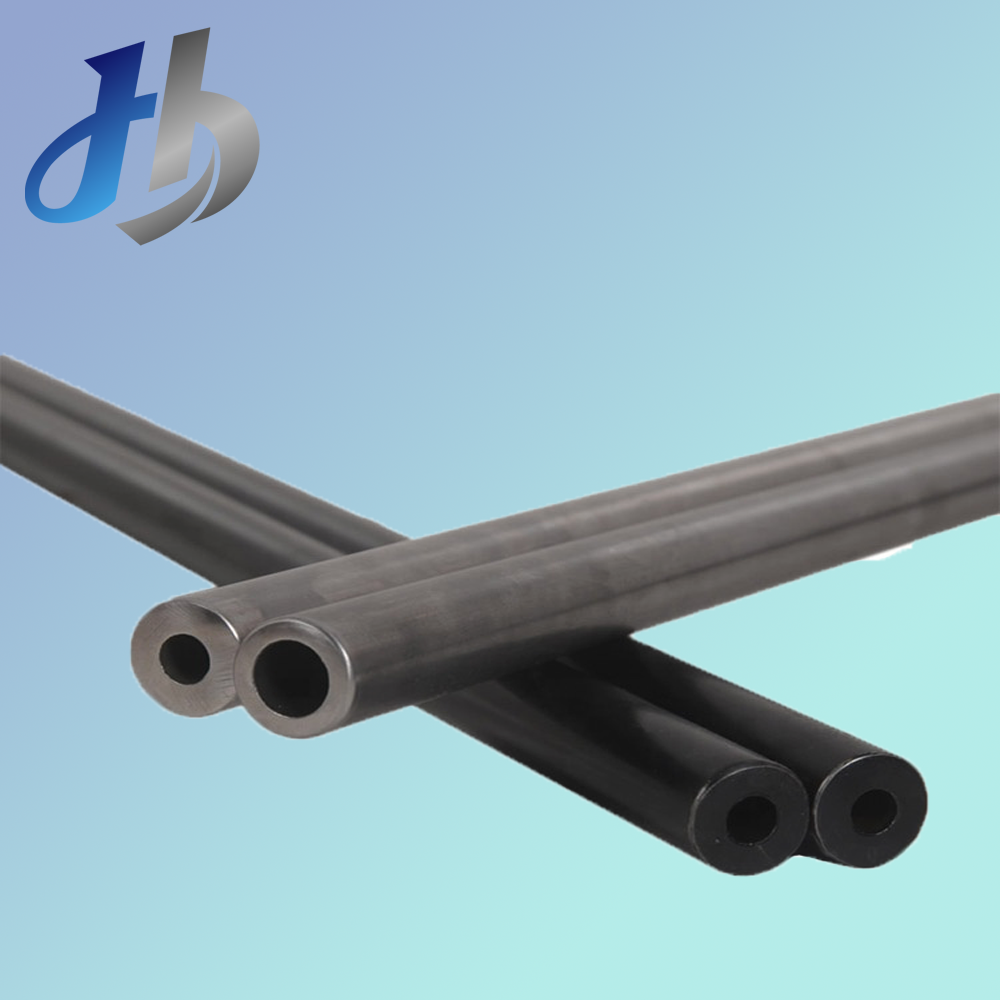

Carbon steel is a widely used and versatile material known for its exceptional strength and durability. Companies like North China Steel specialize in producing high-quality carbon steel pipe, catering to various industries such as manufacturing, construction, and automotive. In this blog, we will explore the different types of carbon steel, their properties, and applications.

What is Carbon Steel?

Carbon steel is an alloy composed primarily of iron and carbon, with trace amounts of other elements. Its carbon content determines its properties and classification into various types: low carbon steel, medium carbon steel, and high carbon steel. Carbon steel pipe accounts for a large portion of steel production globally due to its wide-ranging benefits.

Classification by Carbon Steel Hardness

1. Low Carbon Steel

Low carbon steel, also known as mild steel, typically contains a carbon content ranging from 0.05% to 0.25%. It is the most commonly used type of carbon steel due to its affordability, ease of machining, and good weldability. Low carbon steel is ideal for applications that require moderate strength and ductility, such as structural components, automotive bodies, and sheet metal.

2. Medium Carbon Steel

Medium carbon steel pipe contains a higher carbon content, typically between 0.25% and 0.60%. This type of carbon steel offers better strength and hardness compared to low carbon steel. Medium carbon steel pipe finds applications in gears, axles, and crankshafts where increased durability and wear resistance are required.

3. High Carbon Steel

High carbon steel, also known as tool steel, contains a carbon content ranging from 0.60% to 1.0%. With its superior hardness and ability to hold a sharp edge, high carbon steel is widely used in tools, cutting blades, and springs. However, this type of carbon steel is more brittle and less ductile, making it more challenging to form and weld.

Two Common Grades of Carbon Steel Pipe

1. 1045 Carbon Steel Pipe

1045 carbon steel pipe is a medium carbon steel with a carbon content of approximately 0.45%. It offers excellent strength, durability, and impact resistance, making it suitable for applications such as shafts, gears, and mounting plates. This type of carbon steel can be heat-treated to further enhance its mechanical properties.

2. 1060 Carbon Steel Pipe

1060 carbon steel is a high carbon steel with a carbon content of around 0.60%. It is known for its exceptional hardness and toughness. Due to its high carbon content, 1060 carbon steel is commonly used in swords, knives, and other blades that require both sharpness and strength.

Density of Carbon Steel

The density of carbon steel pipe varies depending on its composition and type. Generally, the density ranges from 7.85 g/cm³ to 8.05 g/cm³. High carbon steel tends to have a slightly higher density due to its increased carbon content. The density of carbon steel is an important factor to consider when designing structures or calculating material requirements.

Conclusion

Understanding the different types of carbon steel, such as low carbon steel, medium carbon steel, and high carbon steel, is essential for choosing the right material for various applications. North China Steel, a leading steel company, specializes in producing high-quality carbon steel tailored to meet industry-specific requirements. By considering factors like carbon content, density, and mechanical properties, one can make informed decisions when selecting the appropriate carbon steel for their projects