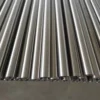

Stainless steel pipe is a kind of hollow long round steel, which is mainly widely used in industrial transportation pipelines and mechanical structural components such as petroleum, chemical industry, medical treatment, food, light industry, mechanical instrumentation, etc. In addition, when the bending and torsional strength are the same, the weight is lighter, so it is also widely used in manufacturing mechanical parts and engineering structures. It is also commonly used as furniture, kitchen utensils, etc.

-Stainless steel pipes generally use Brinell, Rockwell, and Vickers transparency indicators to reduce their hardness.

-The production process of stainless steel seamless pipes:

a. Round steel preparation;

b. heating;

c. hot rolled perforation;

d. cut off the head;

e. pickling;

f. grinding; grinding

g. lubricating;

h. Cold rolling processing;

i. Skim;

j. Solution heat treatment;

k. straighten; straighten

l. cut pipe;

m. pickling;

n. Product testing.

Stainless steel pipes are divided into two categories: seamless pipes and welded pipes according to production methods. Seamless steel pipes can be divided into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes and extruded pipes. Cold-drawn and cold-rolled pipes are the secondary processes of steel pipes. Processing; welded pipes are divided into straight seam welded pipes and spiral welded pipes, etc.

-Stainless steel welded pipe production process:

Raw materials–slitting–welding pipe making–end trimming–polishing–inspection (printing)–packaging–shipping (warehousing) (decorative welded pipe)

Raw materials – slitting – welding pipe making – heat treatment – correction – straightening – trimming – pickling – hydraulic test – inspection (printing) – packaging – shipping (warehousing) (Welded pipe for industrial piping).

-Stainless steel pipe specifications:

φ6-12×1.5-2.5, φ14×1.5-2.5-3, φ16×1.5-2.5-4, φ18×2.3-4-5, φ20×2.5-3-5, φ24×2.5-3-4-5-6, …φ95×4.5-6-8, φ102×4.5-5-6-10-12-14-16-20, φ152×4.5-6-10-12-14,…φ219×6-8-12-16-18-20-25

-Steel pipe size and allowable deviation:

D1: ±1.5%,Min ±0.75mm; D2: ±1%,Min ±0.50mm; D3: ±0.75%,Min ±0.30mm; D4: ±0.5%,Min ±0.10mm

S-Nominal wall thickness of steel pipe, mm;

D-Nominal outer diameter of steel pipe, mm.

W=(outer diameter-wall thickness)×wall thickness×0.02491=KG/M (weight per meter)

-Classification of SS Tube

Stainless steel pipes can be divided into Cr series (400 series), Cr-Ni series (300 series), Cr-Mn-Ni (200 series) and precipitation hardening series (600 series) according to their composition.

200 Series—Chromium-Nickel-Manganese Austenitic Stainless Steel 300 Series—Chromium-Nickel Austenitic Stainless Steel.

301—–Good ductility, used for molded products. It can also be hardened by mechanical processing. Good weldability. Wear resistance and fatigue strength are better than 304 stainless steel.

302—–The corrosion resistance is the same as that of 304, but the strength is better due to the relatively higher carbon content.

303—–By adding a small amount of sulfur and phosphorus, it is easier to cut than 304.

304—–i.e. 18/8 stainless steel. The GB grade is 0Cr18Ni9. 309—has better temperature resistance than 304.

316—–After 304, the second most widely used steel type, mainly used in the food industry, pharmaceutical industry and surgical equipment, the addition of molybdenum element gives it a special corrosion-resistant structure. Because it has better resistance to chloride corrosion than 304 stainless steel pipes, it is also used as “marine steel”. SS316 is usually used in nuclear fuel recovery devices. Grade 18/10 stainless steel pipe also generally meets this application grade.

SS321—Similar to 304 except that the addition of titanium reduces the risk of material weld corrosion.

400 Series—ferritic and martensitic stainless steels.

408—Good heat resistance, weak corrosion resistance, 11% Cr, 8% Ni.

409 – the cheapest model (British and American), commonly used as automobile exhaust pipes, is a ferritic stainless steel (chromium steel).

410—Martensite (high-strength chromium steel), good wear resistance, poor corrosion resistance.

416—The addition of sulfur improves the material’s processing properties.

420—”Cutting grade” martensitic steel, similar to Brinell high chromium steel, the earliest stainless steel. Also used in surgical knives, which can be made very shiny.

430—ferritic stainless steel, for decorative purposes, such as automotive accessories. Good formability, but poor temperature resistance and corrosion resistance.

440—High-strength cutting tool steel with slightly higher carbon content. After appropriate heat treatment, it can obtain higher yield strength and its hardness can reach 58HRC, which is among the hardest stainless steels. The most common application example is “razor blades”. There are three commonly used models: 440A, 440B, 440C, and 440F (easy-to-process type).

500 Series—Heat-resistant chromium alloy steel.

600 Series—Martensitic precipitation hardened stainless steel tubing.