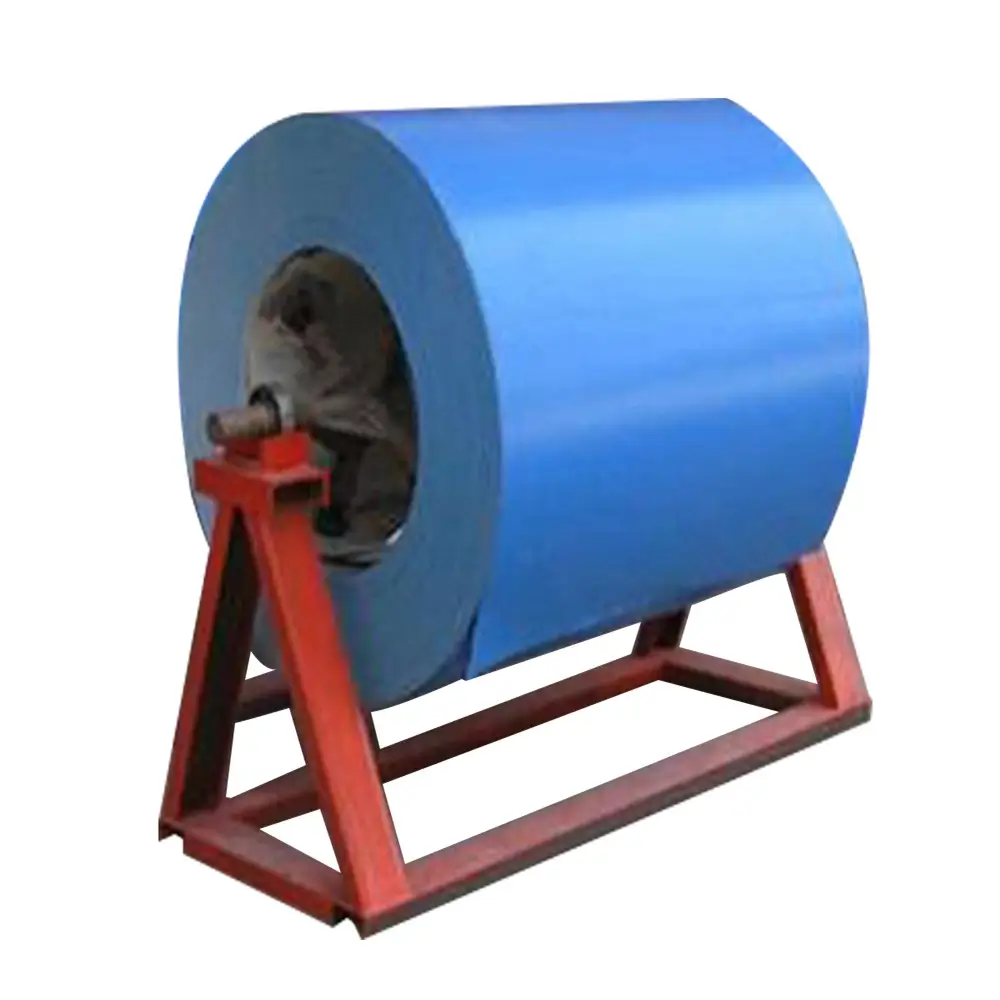

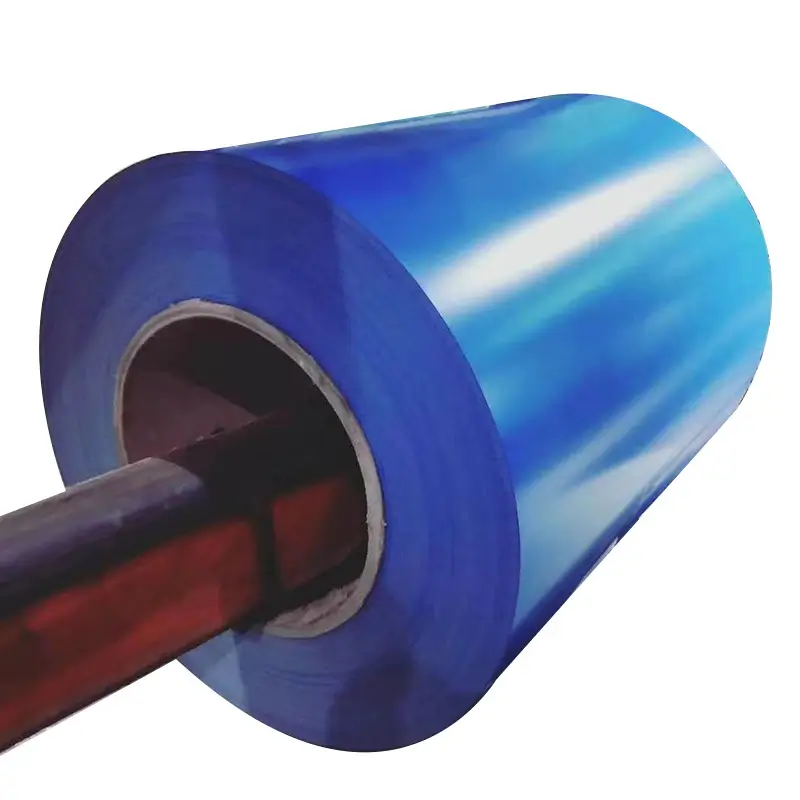

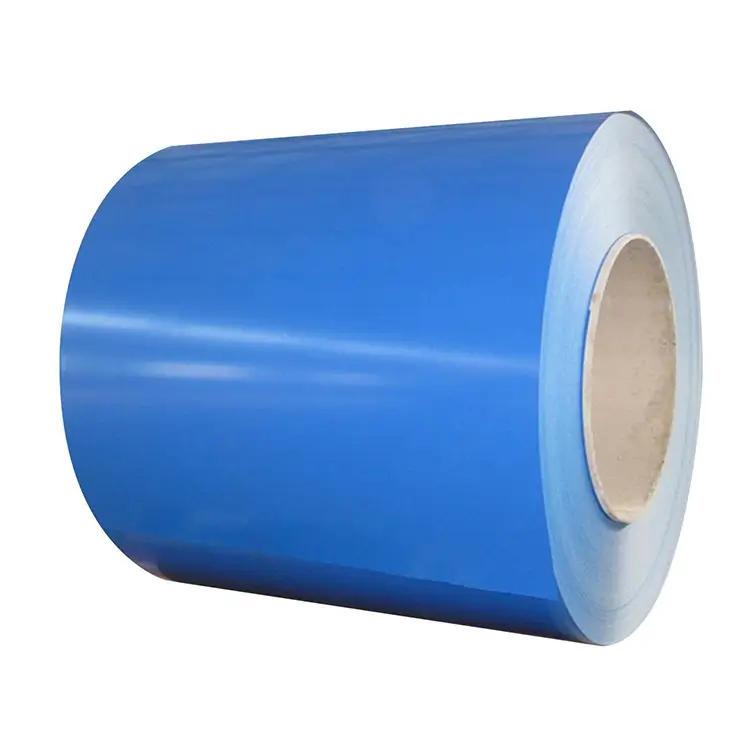

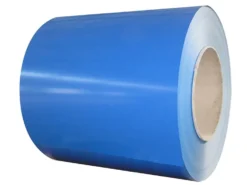

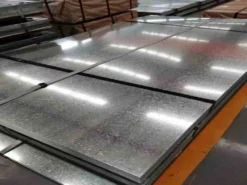

Color-coated coil is based on hot-dip galvanized sheet, hot-dip galvanized sheet, electro-galvanized sheet, etc. After surface pretreatment (chemical degreasing and chemical conversion treatment), one or several layers of organic coatings are applied on the surface, and then A product that is baked and cured. It is named after the colored steel coils coated with various colors of organic coatings, referred to as color-coated coils.

The color-coated steel strip using hot-dip galvanized steel strip as the base material is not only protected by the zinc layer, but the organic coating on the zinc layer plays a covering and protective role to prevent the steel strip from rusting, and its service life is longer than that of the galvanized strip, about 1.5 times.

-The production process of color coated roll

The production of color-coated steel coils is usually divided into two steps: coating preparation and coating process. Coating preparation refers to preparing the color coating into a state suitable for coating, including the formula design, production process, quality control and other aspects of the coating. The coating process refers to the application of color coatings on the steel plate, usually in two ways: roller coating and spraying. Roller coating is to apply color coating on the steel plate, and then use roller equipment to carry out processes such as calendering, drying and curing. Spraying is to spray the color coating on the steel plate, and then use drying and curing equipment for post-processing.

-Characteristics of prepainted steel coils

1. Aesthetic performance: Color-coated steel coils have rich colors and textures, which can meet different design requirements in the fields of construction and home appliances. At the same time, the surface of the color-coated steel coil is smooth and flat, and has a good decorative effect.

2. Corrosion resistance: The surface coating of color-coated steel coils has excellent corrosion resistance and can be used in harsh environments for many years without damage.

3. Weather resistance: The surface coating of the color-coated steel coil has excellent weather resistance, which can resist the erosion of natural environments such as sunlight, rain and wind, and maintain a long-term stable appearance.

4. Mechanical properties: Color-coated steel coils have high mechanical strength and rigidity, and can withstand the load of building structures and mechanical equipment.

5. Processing performance: Color-coated steel coils can be processed by cold bending, stamping, shearing and welding, and have good processing performance and formability.

-Application of color coated steel coil

1. Construction field: Color-coated steel coils are widely used in construction roofs, wall panels, doors and windows, roof trusses, partition walls and ceilings. Color-coated steel coil not only has beautiful performance, but also has good waterproof, fireproof and heat insulation performance, and is an excellent building material.

2. Household appliances: Color-coated steel coils are widely used to make housings for home appliances, such as refrigerators, air conditioners, washing machines, microwave ovens and electric ovens. The color-coated steel coil has the characteristics of wear resistance, anti-corrosion, easy cleaning and beautiful appearance, which can meet the requirements of the home appliance industry for appearance and performance.

3. Transportation field: Color-coated steel coils can be used to make parts such as body shells, roofs, chassis and frames. Prepainted steel coil has the characteristics of light weight, high strength, corrosion resistance, wear resistance and aesthetics, which can improve the safety and aesthetics of transportation tools.

4. Furniture field: Color-coated steel coils can be used to make office furniture, kitchen furniture, bookshelves, wardrobes and other furniture. Prepainted steel coil has the characteristics of beauty, wear resistance, easy cleaning and corrosion resistance, which can meet the requirements of the furniture industry for the appearance and performance of materials.

5. Electronic equipment field: Color-coated steel coils can be used to make electronic equipment casings such as TV casings, audio casings, and computer casings. Prepainted steel coil has the characteristics of beauty, wear resistance, corrosion resistance and anti-electromagnetic interference, which can improve the safety and aesthetics of electronic equipment.