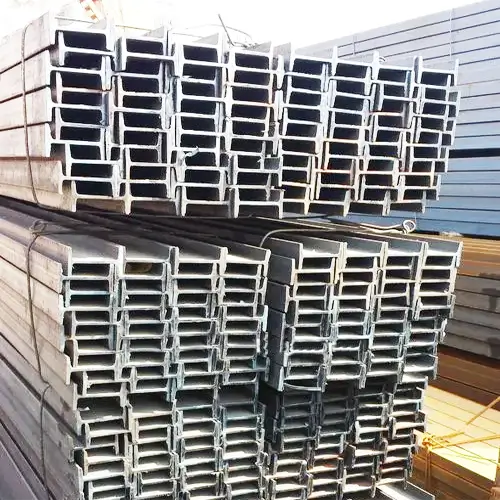

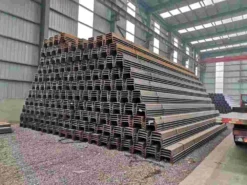

H-shaped steel is an economical cross-section profile with a cross-section shape similar to the capital Latin letter H. It is also called universal steel beam, wide edge (edge) I-beam or parallel flange I-beam. The cross section of H-shaped steel usually includes two parts: web and flange plate, also known as waist and edge.

-Production Method:

H-shaped steel can be produced by welding or rolling. Welding H-shaped steel is to cut strip steel with suitable thickness into suitable width, and weld the flange and web together on a continuous welding unit. Welding H-shaped steel has the disadvantages of high metal consumption, difficulty in ensuring uniform product performance, and limited size specifications. Therefore, H-shaped steel is mainly produced by rolling method. In modern steel rolling production, universal rolling mills are used to roll H-shaped steel. The web of the H-shaped steel is rolled between the upper and lower horizontal rollers, and the flange is rolled simultaneously between the sides of the horizontal rollers and the vertical rollers. Since the flange edge cannot be pressed down by the universal rolling mill alone, it is necessary to set up an edge rolling machine behind the universal rolling mill, commonly known as a flange rolling machine, in order to press down the flange edge and control the flange width. . In the actual rolling operation, the two stands are used as a group to make the rolled piece pass back and forth several times (Figure 2a), or the rolled piece is made to pass through several universal stands and one or two edge rolling end stands. The continuous rolling mill group consists of a certain amount of reduction in each pass to roll the blank into products with required specifications, shapes and sizes.

In the flange area of the rolled piece, due to the sliding between the side of the horizontal roller and the rolled piece, the wear of the roll is relatively large. In order to ensure that the rolls can return to their original shape after heavy rolling, the sides of the upper and lower horizontal rolls of the roughing mill unit and the corresponding vertical roll surfaces should have an inclination angle of 3° to 8°. In order to correct the inclination angle of the finished product flange, a finished product universal rolling mill, also called a universal finishing mill, is set up. The side of the horizontal roll is perpendicular to the axis of the horizontal roll or has a small inclination angle, generally not more than 20′, and the vertical roll is cylindrical.

-Representing Method

H-shaped steel is divided into three categories: wide-flange H-shaped steel (HK), narrow-flange H-shaped steel (HZ) and H-shaped steel column (HU). The expression method is: height Hx width Bx web thickness t1x wing plate thickness t2. For example, H-shaped steel Q235\SS400: 200x200x8x12 is expressed as a wide-flange H-shaped steel with a height of 200mm and a width of 200mm, a web thickness of 8mm, and a wing plate thickness of 12mm. The grade is Q235 or SS400.

-Advantages of Hot Rolled H Beam

1.Steel structures based on hot-rolled H-shaped steel have a high degree of industrial manufacturing, are convenient for mechanical manufacturing, intensive production, high precision, easy installation, and easy to ensure quality.

2.The construction speed of the project is fast, the area is small, and it is suitable for all-weather construction and is less affected by climate conditions.

3.Increase the effective use area of the structure

4.Compared with welding H-shaped steel, it significantly saves labor and materials, reduces raw material, energy and labor consumption, has low residual stress, and has good appearance and surface quality.

5.Facilitates machining, structural connection and installation. Also easy to dismantle and reuse.