Detailed introduction:

-Hardness

Stainless steel pipes generally use three hardness indicators: Brinell, Rockwell, and Vickers to measure their hardness.

-Brinell hardness

Among stainless steel pipe standards, Brinell hardness is the most widely used. The indentation diameter is often used to express the hardness of the material, which is both intuitive and convenient. But it is not suitable for steel pipes made of -Harder or thinner steel.

-Rockwell hardness

The Rockwell hardness test of stainless steel pipe is the same as the Brinell hardness test, which is an indentation test method. The difference is that it measures the depth of the indentation. Rockwell hardness test is currently a widely used method, among which HRC is used in steel pipe standards second only to Brinell hardness HB. Rockwell hardness can be used to measure metal materials from extremely soft to extremely hard. It makes up for the shortcomings of the Brinell method. It is simpler than the Brinell method and the hardness value can be read directly from the dial of the hardness machine. However, due to its small indentation, the hardness value is not as accurate as the Brinell method.

-Vickers hardness

The Vickers hardness test of stainless steel pipe is also an indentation test method that can be used to determine the hardness of very thin metal materials and surface layers. It has the main advantages of Brinell and Rockwell methods and overcomes their basic shortcomings, but it is not as simple as Rockwell method. Vickers method is rarely used in steel pipe standards.

-Hardness testing

The hardness of the inner wall of the pipe can also be tested with a Rockwell or surface Rockwell hardness tester.

The production process of stainless steel seamless pipes:

a. Round steel preparation;

b. heating;

c. hot rolled perforation;

d. cut off the head;

e. pickling;

f. grinding; grinding

g. lubricating;

h. Cold rolling processing;

i. Skim;

j. Solution heat treatment;

k. straighten; straighten

l. cut pipe;

m. pickling;

n. Product testing.

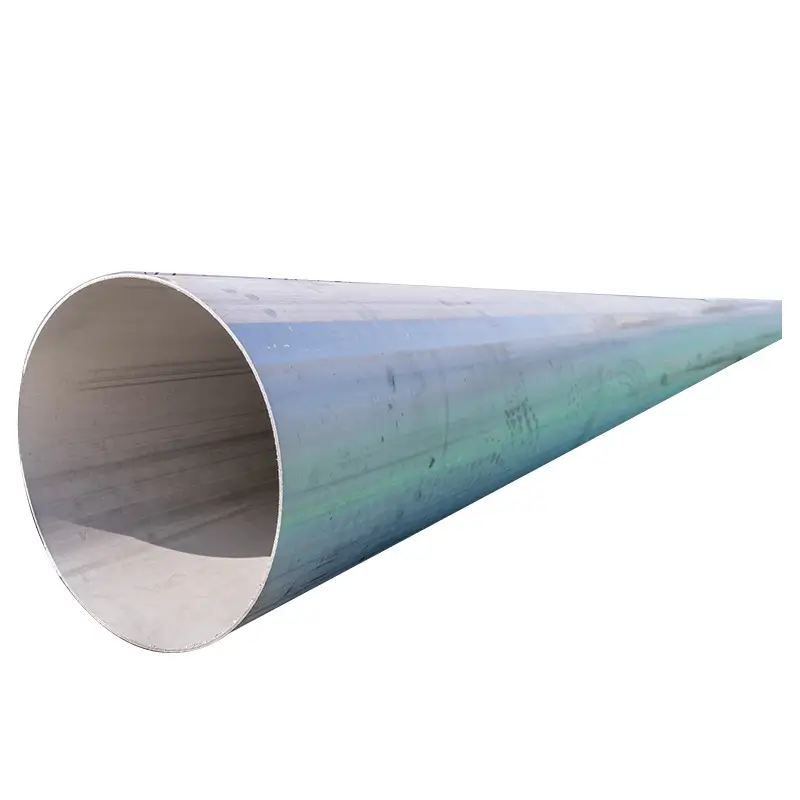

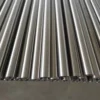

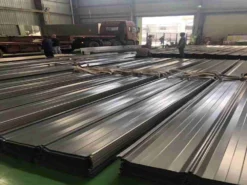

Classification: Stainless steel pipes are divided into two categories: seamless pipes and welded pipes according to production methods. Seamless steel pipes can be divided into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes and extruded pipes. Cold-drawn and cold-rolled pipes are the secondary processes of steel pipes. Processing; welded pipes are divided into straight seam welded pipes and spiral welded pipes.

Stainless steel pipe implementation standards:

GB/T14976-2012 Stainless steel seamless steel pipes for fluid transportation

(Replace GB/T14976-2002, replace GB/T14976-1994, replace GB2270-1980)

GB/T14975-2012 Stainless steel seamless steel pipes for structural use (replacing GB/T14975-2002)

GB13296-2013 Stainless steel tubes for boiler tubes and heat exchangers

(GJB2608-96) (YB676-73) Aviation structural pipes, thick-walled seamless steel pipes

(GJB2296-95) (YB678-71) Stainless steel pipe for aviation

(YB/T679-97) (YB679-71) 18A hollow rivet thin-walled seamless steel pipe for aviation

(GJB2609-96) (YB680-71) Aviation structural pipes, thin-walled seamless steel pipes

(YB/T681-97) (YB681-71) Aviation conduit 20A thin-walled seamless steel pipe

GB3090-2000 small diameter stainless steel pipe

GB5310-2017 Seamless steel pipe for high-pressure boilers

GB3087-2008 low and medium pressure boiler tubes

GB3089-2008 Stainless acid-resistant extremely thin-walled seamless steel pipe

GB9948-2013 Seamless steel for petroleum cracking

ASTM A213 Ferritic and austenitic alloy tubes for boilers and heat exchangers

ASTM A269 General Purpose Austenitic Stainless Steel Pipe and Welded Pipe

ASTM A312 austenitic stainless steel seamless steel pipe welded steel pipe welded pipe

ASTM A450 General Requirements for Carbon, Ferritic and Austenitic Alloy Steel Pipe

ASTM A530 General Requirements for Ferrous and Alloy Steels for Special Purposes

ASTM A789 General Requirements for Carbonitic Austenitic Stainless Steel Seamless and Welded Steel Pipe

JIS G3456-88 Stainless steel pipes for mechanical structures

JIS G3448-88 Stainless steel pipes for ordinary pipes

JIS G3459-88 Stainless steel pipes for pipelines

JIS G3463-88 Stainless steel tubes for boilers and heat exchangers

Q/HYAD seamless steel pipe for chemical industry

(0Cr18NI11T) Q/HYAD Cr18Ni5MO3Si2 duplex stainless steel seamless steel pipe