Part 1 Product Description

Hot rolling can be divided into ordinary carbon structural steel, low alloy steel and alloy steel according to its material and performance. According to different uses, it can be divided into: steel for cold forming, structural steel, automotive structural steel, corrosion-resistant structural steel, mechanical structural steel, steel for welding gas cylinders and pressure vessels, steel for pipelines, etc.

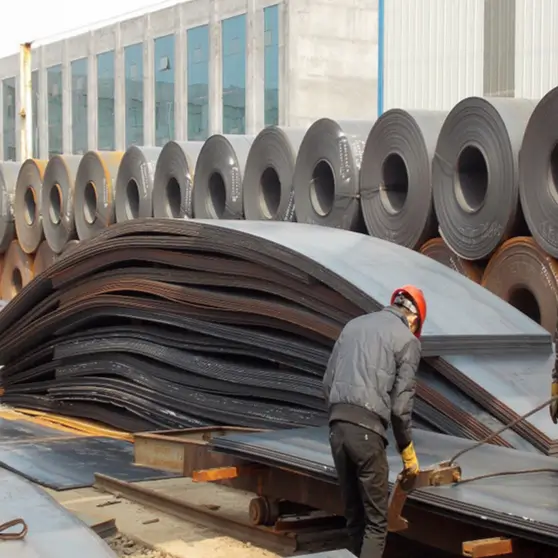

Hot-rolled coil, is made of continuous casting slab or blooming slab as raw material, heated by a walking furnace, descaled by high-pressure water, and then enters the rough rolling mill. Controlled rolling, laminar cooling (computer controlled cooling rate) and coiler coiling after final rolling to become straight hair coils. Coil Inner diameter is 760mm, Uses for ships, cars, bridges, HRB>90. The straight hair coils are often tongue-shaped and fish-tail-shaped, with poor thickness and width accuracy, and the edges often have defects such as wavy, hemmed, and tower-shaped. Its coil weight is heavy. (The general pipe industry likes to use).

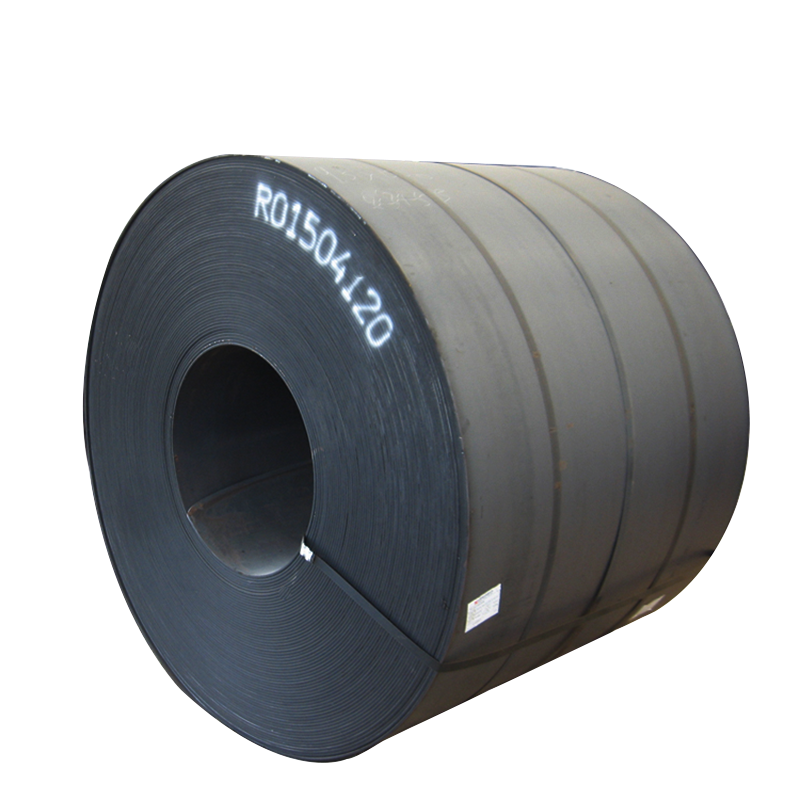

| Commodity: | Carbon steel coil |

| Standard: | DIN GB JIS BA AISI ASTM EN GOST ETC. |

| Mechnical: | Commercial / Drawing / Deep Drawing /Extra Deep Drawing/Structural quality |

| Surface treatment: | Chromated and oiled, and ant-ifinger |

| Hardness: | Softy, half hard ,hard quality |

| Grade: | DC01 |

| ST14,ST15,ST16,DC01,DC03,DC04,DC05,DC06,etc. | |

| Thickness: | 0.12-12.0mm |

| Width: | 600-1500mm |

| Coil weight: | 3-34MT/Coil or as your request |

| MOQ: | 5MT |

| Packaging: | Export standard, seaworthy |

| ID: | 508mm or 610mm |

| Trade Term: | FOB, CFR, CIF, EXW ETC. |

| Transport Type: | Container, bulk and train |

Part 2 Usage

Hot-rolled coils use slabs (mainly continuous casting slabs) as raw materials, and after heating, they are made into strip steel by rough rolling units and finishing rolling units. The hot-rolled coil comes out of the last rolling mill of the finishing rolling and is cooled to the set temperature by laminar flow, and is rolled into a steel coil by the coiler. The cooled steel coil passes through different processes according to the different needs of users. The finishing line (leveling, straightening, cross-cutting or slitting, inspection, weighing, packaging and marking, etc.) is processed into steel plate, flat coil and slitting steel strip products.

To put it simply, a billet is heated and rolled several times, then trimmed and straightened into a steel plate. This processing method is called hot rolling.

Due to the high strength, good toughness, easy processing and good weldability of hot-rolled steel products, they are widely used in manufacturing industries such as ships, automobiles, bridges, construction, machinery, and pressure vessels.

With the increasing maturity of new technologies for controlling hot-rolled dimensional accuracy, plate shape, and surface quality, and the continuous emergence of new products, hot-rolled steel sheets and strip products have been more and more widely used and have become more and more powerful in the market. competitiveness.

Part 3 Steel grades

1. SPHC—the abbreviation of the first S steel Steel, P is the abbreviation of Plate, H is the abbreviation of Heat, and C is the abbreviation of Commercial. The whole indicates that hot-rolled steel plates and steel strips are generally used.

2. SPHD——Indicates hot-rolled steel sheets and strips for stamping.

3. SPHE——Indicates hot-rolled steel sheets and strips for deep drawing.

4. SPCC——Indicates cold-rolled carbon steel sheets and strips for general use. The third letter C is the abbreviation of Cold. When it is necessary to ensure the tensile test, add T at the end of the grade to represent SPCCT.

5. SPCD——indicates cold-rolled carbon steel sheet and strip for stamping

6. SPCE——Indicates cold-rolled carbon steel sheet and strip for deep drawing. When it is necessary to ensure non-timeliness, add N at the end of the grade to be SPCEN.

Quenching and tempering code for cold-rolled carbon steel sheet and steel strip: A for annealed state, S for standard quenching and tempering, 8 for 1/8 hard, 4 for 1/4 hard, 2 for 1/2 hard, 1 for hard. Surface processing code: D for dull finish rolling, B for bright finish rolling. For example, SPCC-SD means standard quenched and tempered, matte finish rolled general cold rolled carbon sheet. Another example is SPCCT-SB, which means standard quenching and tempering, bright processing, and cold-rolled carbon sheets that require guaranteed mechanical properties.

7. The method of expressing the steel grade for JIS mechanical structure is: S + carbon content + letter code (C, CK), where the carbon content is expressed by the median value × 100, the letter C: indicates carbon K: indicates carburizing steel. For example, carbon knot coil S20C has a carbon content of 0.18-0.23%.

How to Contact Us

Deliver on time

Phone:86 186 6042 1547(WhatsApp)

Competitive price

Free shipping

Add : 506, West Tower of Sunuo City, Huaiyin District, Jinan