Part 1 Product Description

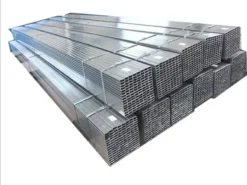

| Product name | Galvanized Steel Pipe |

|---|---|

| Material | 10#, 20#, 45#, 16Mn, A53(A,B), Q235, Q345, Q195, Q215, St37, St42, St37-2, St35.4, St52.4, ST35 etc. |

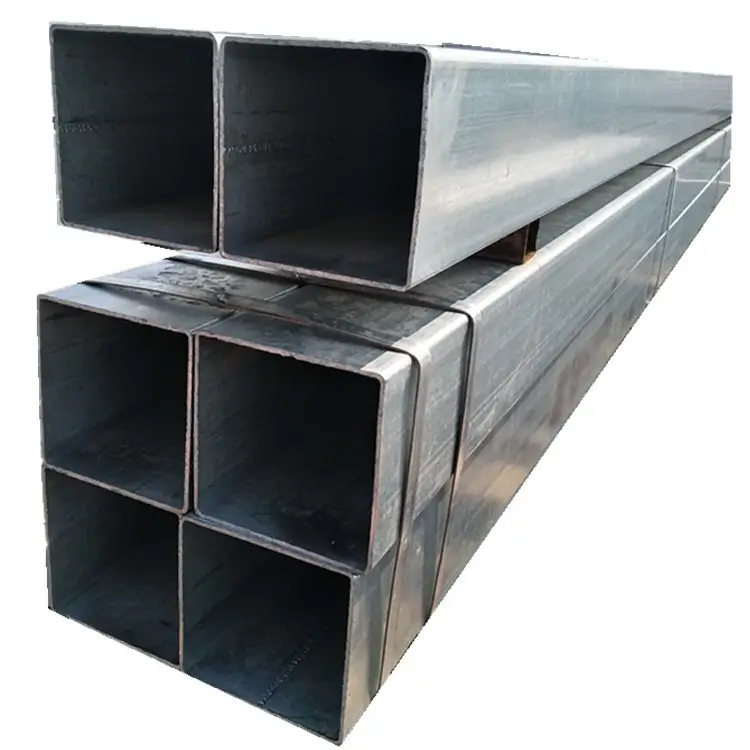

| Wall Thickness | 1MM~12MM or as your requirement |

| Outer Diameter | 20MM~508MM or as your requirement |

| Length | Length:Single random length/Double random length5m-14m,5.8m,6m,10m-12m,12m or as customer’s actual reques |

| Standard | API 5L, ASTM A53-2007, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M-2004, ASTM A523-1996, BS 1387, BS EN10296, BS6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 etc. |

| Grade | 10#-45#, 16Mn, A53-A369, Q195-Q345, ST35-ST52Grade A, Grade B, Grade C |

| Technique | Hot Dip Galvanized Round Steel Pipe |

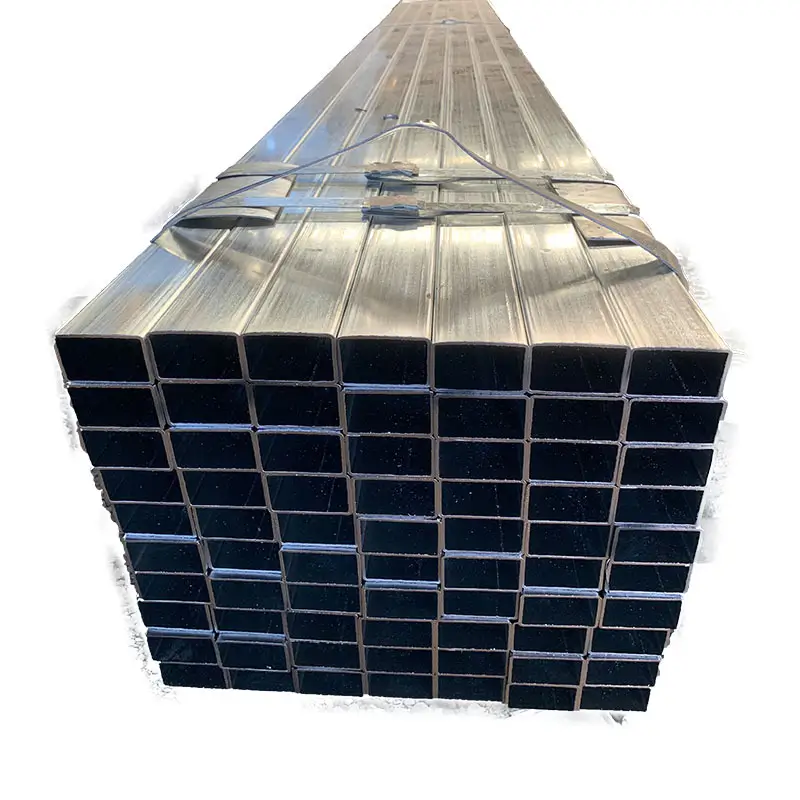

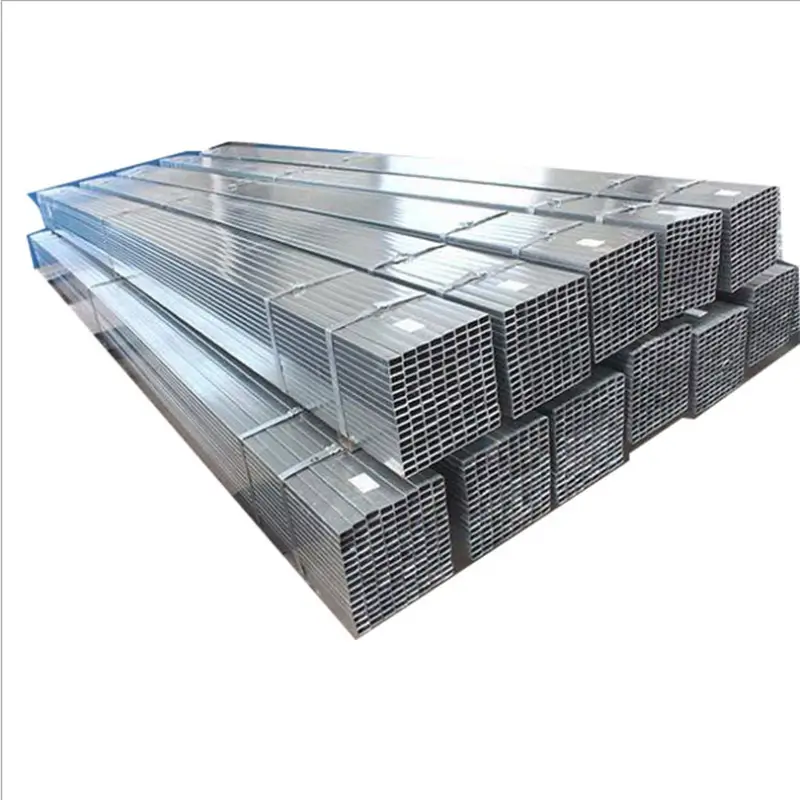

| Packing | Bundle, or with all kinds of colors PVC or as your requirements |

| Pipe Ends | Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc. |

| Surface Treatment | 1. Galvanized2. PVC,Black and color painting3. Transparent oil,anti-rust oil4. According to clients requirement |

| MOQ | 1 Ton |

| Delivery Time | within 7 days,According to the quantity of goods required by the customer |

Part 2 Specification Classification

1. Small Specification

DN15, DN20, DN25, DN32, and DN40 are small-sized galvanized steel pipes, which are frequently used in daily life. Their respective outer diameters are different, respectively 21.3mm, 26.9mm, 33.7mm, and 42. mm and 48.3mm.

2. Medium Specification

DN50, DN65, DN80, and DN100 models belong to medium-sized galvanized steel pipes. Their outer diameters range from 60.3mm to 114.3mm, and the thickness of the pipe wall is also different, such as 3.5mm, 3.8mm, and 4mm. The weight also increases

3. Big Specification

DN125, DN200, DN450 and other models belong to large-scale galvanized steel pipes. Their outer diameters are relatively large, with different sizes such as 140mm and 219.1mm, and the wall thickness and weight also increase accordingly.

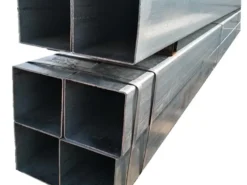

Part 3 Classification of Galvanized Steel Pipe

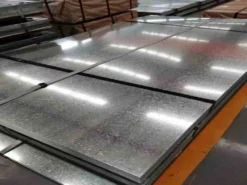

1. Hot-dip galvanized pipe

This type of galvanized pipe is pickled first to remove the iron oxide on the surface. After the pickling is completed, ammonium chloride and zinc chloride are mixed together, used to clean the tank, and then sent to the hot water. dipping tank. For hot-dip galvanized pipe, the coating on it is very uniform and has strong adhesion, and of course the service life is relatively long.

2. Cold galvanized pipe

Cold-dip galvanizing is actually electro-galvanizing, and the amount of galvanizing in it is very small, so the corrosion resistance is much worse than that of hot-dip galvanized pipe. For regular manufacturers, in order to ensure the quality of the pipeline during the production process, they will basically not use electro-galvanizing. For manufacturers with small scale and outdated equipment, they will use electro-galvanized, because the cost will be lower and their own profits will be higher, so everyone should pay attention when buying.

Galvanized steel pipe is a welded steel pipe with a hot-dip or electro-galvanized layer on the surface. Galvanizing can increase the corrosion resistance of steel pipes and prolong their service life. Galvanized pipes are widely used. In addition to being used as pipeline pipes for general low-pressure fluids such as water, gas, and oil, they are also used as oil well pipes and oil pipelines in the petroleum industry, especially offshore oil fields, and oil heaters and condensation pipes for chemical coking equipment. Pipes for coolers, coal distillation washing oil exchangers, trestle piles, and support pipes for mine tunnels, etc.