| Product Name | Galvanized Steel Sheet |

|---|---|

| Standard and Materia | SGCC;SGCD1;SGCD2;SGCD3;SGC340;SGC400;SGC440;SGC590; |

| DX51D+Z;DX52D+Z;DX53D+Z;DX54D+Z;S250GD+Z; | |

| S280GD+Z;S320GD+Z;S350GD+Z;S550GD+Z;Q-BQB420-2009 | |

| Thickness | 0.13-0.8mm |

| Width | 600-1250mm |

| Zinc coating | 20- 275g/m2 |

| Coil Weight | 3-8 Tons or as requirment |

| Surface Treatment | Mini/Big Spangle |

| Application | Applies to construction field,ships building industryboiler heat exchangerpetroleum chemical industries war and electricitvindustries,food processing and medical industrymachinery and hardware fields. |

| Payment | T/T, L/C, Western Union |

| Packing method | Water proof paper+wooden pallets or as requirements |

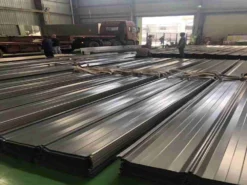

Part 1 Production Description

Galvanized steel sheet is to prevent the surface of the steel sheet from corrosion and prolong its service life. A layer of metal zinc is coated on the surface of the steel sheet. This galvanized steel sheet is called galvanized sheet.

According to the production and processing methods, it can be divided into the following categories:

1.Hot-dip galvanized steel sheet.

Dip the thin steel plate into the molten zinc tank to make the thin steel plate with a layer of zinc adhered to its surface. At present, the continuous galvanizing process is mainly used for production, that is, the coiled steel plate is continuously immersed in a galvanizing tank with molten zinc to make a galvanized steel plate;

2.Alloyed galvanized steel plate.

This kind of steel panel is also made by hot dip method, but it is heated to about 500℃ immediately after coming out of the tank, so that it can form an alloy film of zinc and iron. This galvanized sheet has good paint adhesion and weldability;

3.Electro-galvanized steel plate.

The galvanized steel panel manufactured by electroplating has good processability. However, the coating is thinner and its corrosion resistance is not as good as that of hot-dip galvanized panels;

4. Single-sided galvanized steel and double-sided galvanized steel.

Single-sided galvanized steel sheet, that is, a product that is galvanized on only one side. In terms of welding, painting, anti-rust treatment, processing, etc., it has better adaptability than double-sided galvanized sheet. In order to overcome the shortcomings of one side without galvanizing, there is another kind of galvanized sheet coated with a thin layer of zinc on the other side, that is, double-sided differential galvanized sheet;

5. Alloy, composite galvanized steel.

It is an alloy made of zinc and other metals such as aluminum, lead, zinc, or even a composite plated steel plate. This kind of steel plate not only has excellent antirust performance, but also has good coating performance;

In addition to the above five types, there are also colored galvanized steel panels, printed galvanized steel panels, PVC laminated galvanized steel panels, etc. But the most commonly used is still hot-dip galvanized sheet.

Part 2 Dimension and Specification

0.20-1.2*1000*C, Zinc Coating 80, DX51D+Z

1.2*1050*C,Zinc Coating 150, CSB

1.55*1000*C, Zinc Coating 180, S280GD+Z

1.95*1000*C, Zinc Coating 275, S350GD+Z

The relevant product standards list the recommended standard thickness, length and width of galvanized sheets and their allowable deviations. Generally speaking, the thicker the galvanized sheet, the greater the allowable error, rather than the fixed 0.02-0.04mm. The thickness deviation also has different requirements according to the yield, tensile coefficient, etc. The length and width deviation is generally 5mm, and the thickness of the plate Generally between 0.4-3.2mm.

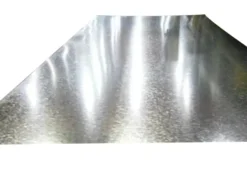

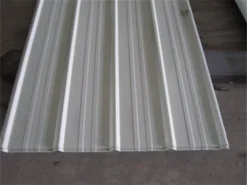

Part 3 Appearance

1.Surface state

Due to the different treatment methods in the coating and plating process, the surface state of galvanized sheets is also different, such as ordinary spangle, fine spangle, flat spangle, non-spangle and phosphating surface. German standards also specify surface grades.

2.Advantages

The galvanized sheet shall have a good appearance and shall not have defects harmful to the use of the product, such as no plating, holes, cracks and scum, excess plating thickness, scratches, chromic acid dirt, white rust, etc. Foreign standards are not very clear about specific appearance defects.